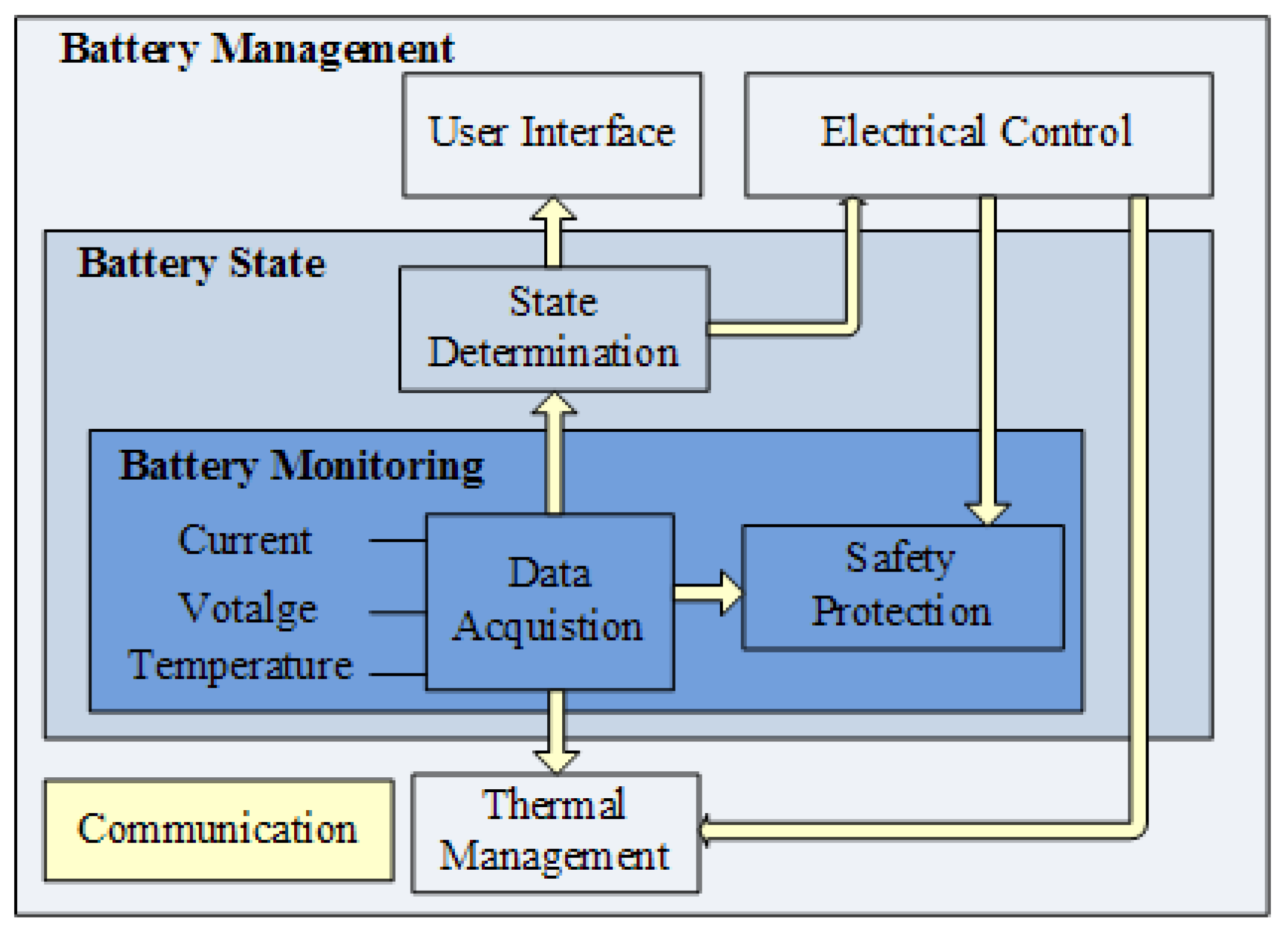

Battery Management System (BMS) in electric vehicles

Hello People. This article is about Battery Management System (BMS) in electric vehicles. Battery is the heart of an electric vehicle. It provides electricity to drive the vehicle. Most commonly used batteries in electric vehicles are Lithium Ion batteries.

An electric vehicle battery is often composed of many hundreds of small, individual Lithium ion cells arranged in a series/parallel configuration to achieve the desired voltage and capacity in the final pack. Lead acid batteries are also used in some cases.

Li-ion-based battery packs include advanced battery management systems to ensure their proper use and safety.

Are you looking to start your business in the electric vehicle industry? We provide software development, web application development, mobile application development, charging stations management app, electric vehicle fleet management software development, cyber security and all software services. Please check our home page here https://iwheels.co/

Ok. Let's get back to the article.

BMS does the following functions

- Read the total voltage

- Read the current from/to the battery

- Read the temperature

- Determine the total charge

- Determine the battery health (by comparing the current capacity against the original capacity)

- Correctly manage regenerative breaking to recharge the batteries

- Detect over current situations

- Detect over-voltage situations

- Detect under-voltage situations

- Detect over-temperature situations

- Detect over-pressure (this is important if the battery starts producing hydrogen)

Algorithm-Designed Cloud-Connected Batteries

Battery technology is benefiting from the power of artificial intelligence through predictive analytics and data intelligence.

Data science, AI, and big data tools are used to improve the performance of battery packs. The predictive maintenance facilitates high battery efficiency and operational reliability.

Machine Learning helps to explore the opportunity of battery life cycle management. The key to improving battery life lies in the data. By blending advanced electronics with IoT, data science and digital twin, Machine Learning uses the power of predictive intelligence to predict battery life, identify potential breakdown and their causes, fix errors even before they arise. All this data can be stored in the cloud.

Ford is planning to use Google’s AI, data science and analytical capabilities to improve customer experiences. It also uses AI to accelerate the modernisation of product development, manufacturing and supply chain management, and fast track the implementation of data-driven business models.

Tesla uses machine learning and artificial intelligence for their over-the-air fix. The engineers could use the AI system to update the software over cloud, saving users a trip to the service center.

PURE EV, an IIT Hyderabad-incubated startup, has come up with an artificial intelligence-driven hardware to repair lithium-ion batteries of electric vehicles automatically. The researchers have developed an Artificial Neural Network (ANN)-based algorithm called ‘BaTRics Faraday’ to identify defects in batteries.

A study, published by Nature on February 19, 2020, a collaboration among scientists from Stanford, MIT and the Toyota Research Institute had a goal of finding the best method for charging an EV battery in 10 minutes that maximizes the battery’s overall lifetime.

Hope this article on Battery Management System (BMS) in electric vehicles is useful to you. To read about jobs in the Electric Vehicle Industry, please visit Job opportunities in Electric Vehicle Sector and its Charging Infrastructure industry